Display Interfaces Explained

High-Reliability Display Electronics for Professional, Industrial, and OEM Systems

Below is an engineering-focused overview of how these interfaces compare and where each is most appropriate.

Video Input Interfaces (Source → Controller)

HDMI (High-Definition Multimedia Interface)

HDMI is widely used for consumer and commercial sources, but is also common in professional systems where compatibility and ease of integration matter.

Key characteristics:

Designed for consumer and commercial video sources

Supports audio, HDCP encryption, and CEC

Bandwidth depends on version (HDMI 1.4 → 4K30; HDMI 2.x → 4K60 and above)

TMDS signaling, moderate cable lengths

When HDMI is used:

Applications requiring broad compatibility with PCs, media players, and embedded systems

Signage, kiosks, broadcast monitoring, general-purpose video display

Integration notes:

Cable quality and length strongly affect signal integrity

HDCP and EDID must be considered when integrating with protected content sources

DisplayPort (DP)

DisplayPort provides higher bandwidth and more robust signaling than HDMI, making it better suited for 4K, 8K, and multi-lane professional applications.

Key characteristics:

Packet-based protocol designed for high performance

Supports multiple lanes for increased bandwidth

Allows daisy-chaining through Multi-Stream Transport (MST)

Excellent signal integrity for higher resolutions

When DisplayPort is used:

High-resolution 4K/8K systems

Professional graphics workstations

Control rooms, medical imaging, simulation, defense

Integration notes:

More tolerant of long cable runs than HDMI

Panel-side integration still requires conversion to eDP, LVDS, or V-by-One via a controller

Panel Interface Technologies (Controller → LCD Panel)

eDP (Embedded DisplayPort)

eDP is a panel interface, not a video input. It is optimized for internal display connections and increasingly common in newer industrial panels.

Key characteristics:

High bandwidth with reduced wiring relative to LVDS

Lower power consumption

Supports features such as Panel Self Refresh

Strong roadmap longevity

When eDP is used:

Newer industrial and commercial LCD panels

Applications needing compact signal routing and lower EMI

Integration notes:

Selection of lane count and link rate is critical

Requires careful attention to cable length and integrity

Controller must match the panel’s exact timing and link configuration

LVDS (Low-Voltage Differential Signaling)

LVDS has been the dominant panel interface for industrial displays for many years.

Key characteristics:

Mature, well-understood technology

Robust in noisy environments

Supports many existing industrial and medical panels

Limited bandwidth compared to eDP and V-by-One

When LVDS is used:

Legacy or long-lifecycle industrial and medical panels

Applications where EMI resilience is critical

Systems requiring predictable behavior over many years

Integration notes:

Cable length and impedance must be tightly controlled

Timing configuration is essential for flicker-free operation

V-by-One (Vx1)

V-by-One is a high-speed serial interface designed to deliver large bandwidth over a small number of differential pairs.

Key characteristics:

Very high data rates per lane

Highly scalable to 4K, 8K, and above

Reduced cable bulk compared to LVDS

Excellent noise immunity

When V-by-One is used:

Large-format displays

High-resolution industrial signage

Broadcast, control, and visualization systems

Integration notes:

Requires strict clocking and timing management

Cable design and EMC control have meaningful impact

Ideal for pairing with Digital View’s high-end 4K/8K controller families

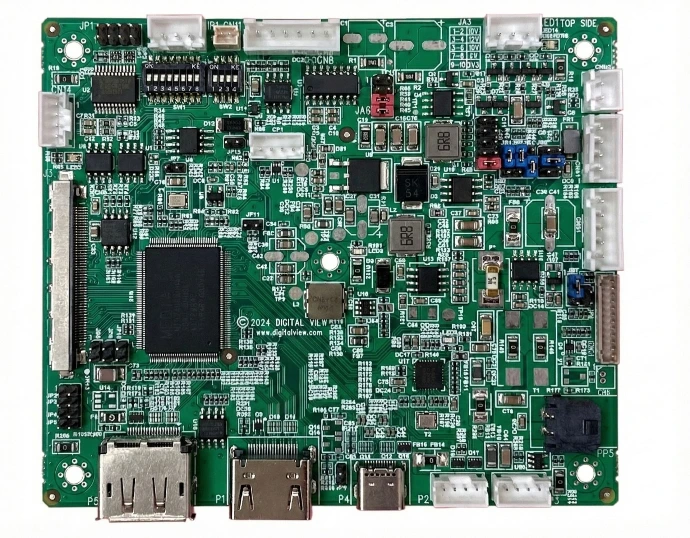

How Digital View Controller Boards Support These Interfaces

Digital View controllers sit at the center of the display architecture, managing the complete signal chain:

Video input → signal processing → panel interface → backlight control

Each controller family supports a specific combination of input formats, processing features, and panel interface technologies.

- Inputs: HDMI, DisplayPort, SDI, and selected analog legacy formats

- Panel outputs: LVDS, eDP, or V-by-One, depending on the model

- Processing: Scaling, gamma adjustment, dithering, color management, and low-latency paths

- Configuration: Firmware profiles for panel-specific timing, EDID management, and operating parameters

This clear separation between video inputs and panel drive interfaces provides OEMs with:

Flexibility to upgrade or change video sources without redesigning the display hardware

A straightforward path to adopt new LCD panels, even when interface technologies evolve

Long-term product stability, supporting extended lifecycles and predictable field performance

Choosing the Right Interfaces for Your Display Application

In display system design, interface choices happen at two different layers:

Video input interface (source → controller) — the designer chooses this.

Panel interface (controller → LCD panel) — the panel dictates this.

The system designer does not choose LVDS, eDP, or V-by-One independently; that decision is made when selecting the LCD panel.

Digital View controllers then ensure compatibility between the chosen panel and the chosen input source.

1. Selecting the Video Input Interface (Source → Controller)

Use HDMI when:

Source compatibility is the priority

The system uses PCs, media players, SBCs, or commercial devices

The application involves signage, kiosks, or general-purpose video streams

Use DisplayPort when:

You require 4K/8K performance or high bandwidth

You need robust transmission or longer cable runs

The application is mission-critical: medical, defense, control rooms, simulation

Use SDI when:

You need long-distance cable runs

You operate in broadcast, surveillance, or rugged environments

(Input interfaces end here — the user does not choose LVDS/eDP/V-by-One at this stage.)

2. Panel Interface (Controller → LCD Panel)

Generally determined by the choice of panel. The following shows some common characteristics - in any case, Digital View has models for each of these.

LVDS:

The panel is a legacy or long-lifecycle industrial/medical display

You need predictable, stable performance in EMI-challenging environments

eDP:

Working with newer, power-efficient industrial or commercial panels

You want fewer conductors and improved EMI performance

V-by-One:

Driving large-format or high-resolution displays (4K, 8K)

High bandwidth and reduced cable bulk are required

Integration Considerations

Cable impedance, shielding, and length dramatically affect signal integrity

EMI/EMC requirements vary by industry—particularly medical, defense, marine, and industrial automation

Timing and clock configuration must match panel specifications exactly

Backlight control, power sequencing, and firmware all contribute to long-term system reliability

Our engineering team supports OEMs with panel validation, configuration guidance, and technical documentation.

Frequently Asked Questions (FAQ)

They operate at different layers of the system and are not interchangeable.

Designers choose the panel, and that choice determines whether LVDS, eDP, or V-by-One is required. The controller must match the panel’s interface.

Choose based on the video source and performance needs:

HDMI for broad compatibility

DisplayPort for high bandwidth (4K/8K) and professional applications

SDI for long-distance or ruggedized environments

The controller will adapt the input format to the panel interface.

- Long lifecycle availability

- EMI robustness

- Predictable, stable behavior

Even as eDP and V-by-One expand, LVDS is maintained for backward compatibility and product longevity.

They translate the incoming video signal (HDMI/DP/SDI) into the panel’s required format (LVDS/eDP/V-by-One), while handling timing, scaling, gamma, color management, EDID, and backlight control. This enables panel changes or source upgrades without redesigning the whole system.

Next Steps

To select the right controller for your display system:

Speak with our engineering team

Request a controller selection review

Provide your panel specifications for compatibility confirmation

Digital View supports OEMs, integrators, and engineering teams throughout the entire product lifecycle—from concept through production.